22/02/21

Hot oil pump bearing lubrication

the bearing oil level is too low, so that some parts of the RY hot oil pump bearing can not be lubricated, so the bearing will produce wear and heat, so that the bearing is burnt out.

Why is the bearing oil level too high or too low bad?

Answer: 1) the bearing oil level is too low, so that some parts of the RY hot oil pump bearing can not be lubricated, so the bearing will produce wear and heat, so that the bearing is burnt out.

2) The oil level is too high, and with the rotation of the spindle, the rolling bearing and the oil ring are easy to leak oil from the shaft seal in the process of carrying oil;

The oil level is too high, and the rotation of the oil ring is hindered, resulting in bearing heating.

What is the oil filling requirement for grease-lubricated bearings?

Answer: 1) For low speed (speed below 1500r/min), the amount of mechanical filling oil is generally not more than two-thirds of the whole bearing chamber;

2) For mechanical filling oil with revolutions above 1500r/min, the amount of oil should not be more than half of the whole bearing chamber in general.

What are the reasons for the high bearing temperature?

Answer: 1) the oil level is too low to reduce the amount of oil entering the bearing.<

2) the oil quality is not qualified, water or into impurities, oil emulsification deterioration;

3) The oil ring does not rotate, and the oil supply of the bearing is interrupted.

4) Insufficient bearing cooling water, 5) bearing damage, 6) bearing gland exerted too much or too little tightening force on bearing or crushed radial clearance, resulting in loss of flexibility.

What are the requirements for the performance of sliding bearing bushing materials?

Answer: 1) there should be enough strength and plasticity, bearing lining can withstand a certain working pressure, and can be evenly distributed with the pressure between the journal.

2) It has good bubble compatibility and wear resistance.

3) Good lubrication and heat dissipation performance.

4) to have good process performance.

What materials should be used to manufacture the tile shell of sliding bearings?

Answer: cast steel, forged steel, cast iron

As a rule of thumb, what is the general radial clearance of the bearing bush?

Answer: according to the different structure of the bearing to take the shaft diameter of 1/1000 to 3/1000.

What is the effect of the clearance size of the sliding bearing?

Answer: 1) small clearance, high accuracy, but too small can not guarantee lubrication, can not form oil film.

2) The clearance is large, the accuracy is low, the operation is easy to produce jump, the oil film is not stable.

RELEVANT

22/02/21

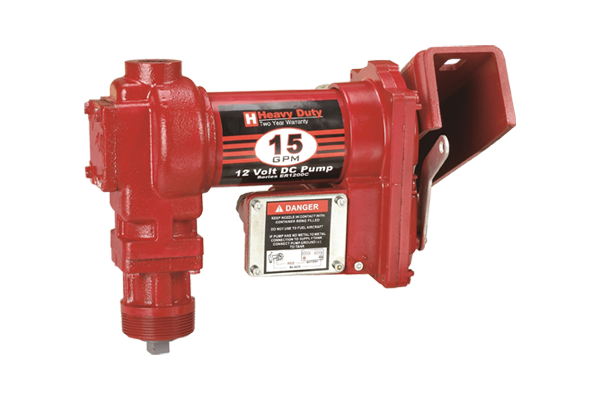

What are the common reasons for the failure of the oil pump

Generally speaking, the mechanical oil transfer pump is very reliable. Even if it fails, it is often the diaphragm rupture that causes insufficient oil transfer. Sometimes the rocker arm or spring of the oil pump is worn out excessively, which will also cause insufficient oil delivery. The fault is easier to identify. The old-fashioned oil pump can be repaired, but the new-style oil pump cannot be disassembled, so it should be replaced once it fails.

22/02/21

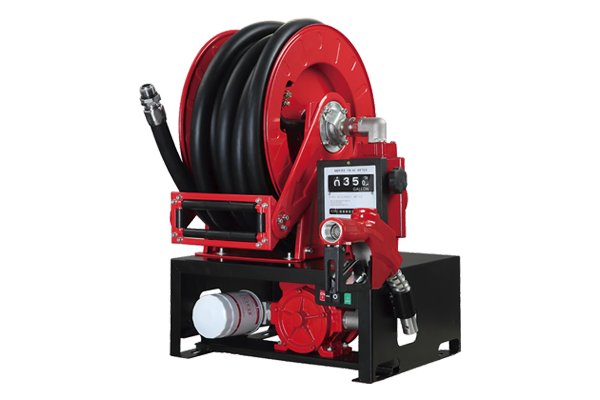

Analysis of the types of oil transfer pumps

Scope of application of KCB oil transfer pump: It is suitable for conveying lubricating oil or other liquids with similar properties to lubricating oil that do not contain solid particles and fibers, are non-corrosive, have a temperature not higher than 150 °C, and have a viscosity of 5 to 1500 cst.

22/02/21

Common faults and countermeasures of electric grease gun

The electric grease gun is a miniature electric grease gun, which consists of a casing, a frame, a plunger pump mechanism, a crank-slider mechanism, a gear reduction mechanism, an oil supply system, an operating system and a power system: its structure is small and the battery is built-in, An external charger can be installed, driven by a DC motor, the price is moderate, labor-saving, fast, easy to operate, high pressure, and can meet the general mechanical oiling requirements.

22/02/21

Precautions and maintenance when using electric grease gun daily

Before use, check whether the valve spring, steel ball and other parts are in short supply, the sealing condition of the piston and the oil gun head, and pay attention to check the squeezing effect to ensure the smooth progress of the maintenance work.